The use of data loggers connected to the CAN bus or the ISOBUS for monitoring agricultural machinery during work has yet a lot to offer to managers and machinery users, if gathered data is analyzed conveniently.

A few years ago, one of the Spanish partners in the Sparkle project, the Polytechnic University of Madrid, performed a field test of a new model of telescopic handler, Manitou MLT 840-137 PS, recently acquired by an enterprise specialized in transporting and handling agricultural produces (grain, hay, forage, etc.). This firm has highly skilled personnel, experts in driving this type of machinery, but they are eager of getting always the most out of their machines, and applying new technologies to their activities in order to optimize them.

Therefore, the UPM team installed several types of sensors on the telescopic handler, such us a very precise GPS with high sampling rate (10Hz) for registering the position of the machine at all times, a set of accelerometers for registering accelerations/decelerations or changes in direction, and a set of temperature sensors and infrared cameras for the registration of possible overheats in the machine components, such as the hydraulic circuits or the mechanical transmissions (gear boxes).

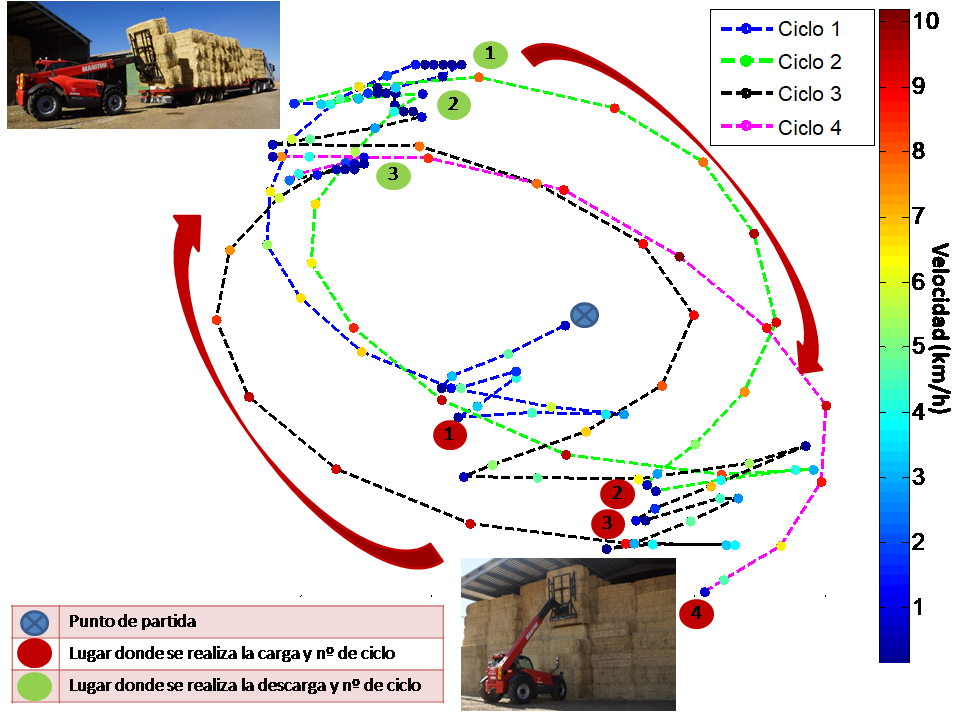

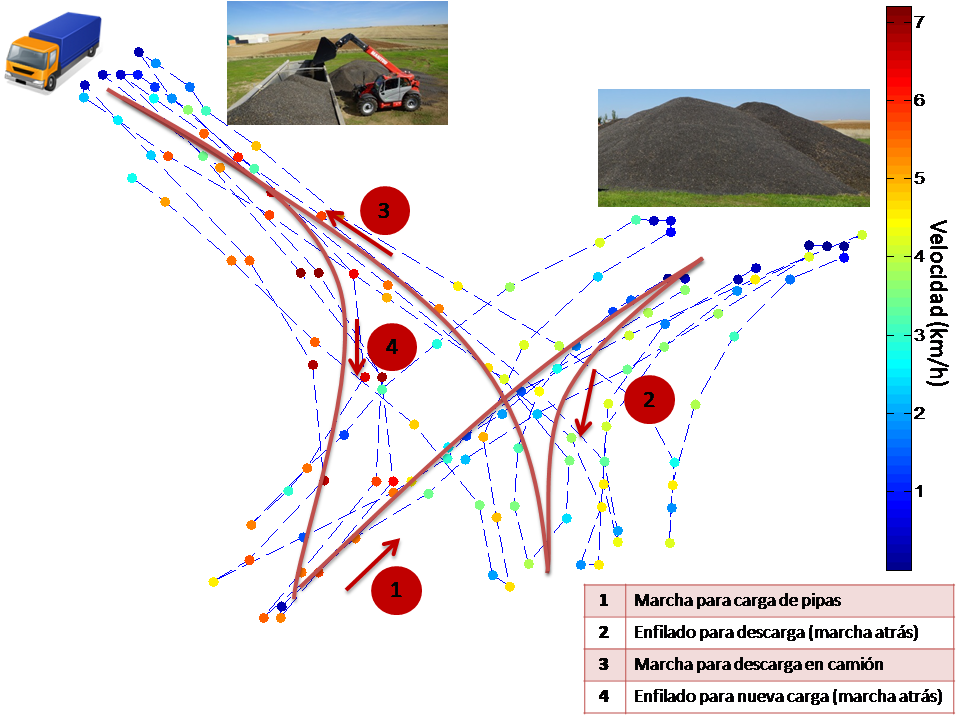

As a result, due to the analyses of the position of the machine at every moment while working, it was possible to establish recommendation for its optimization. The loader was registered while it was performing two types of work: A) unloading a transport of hay packages in order to fill a hay warehouse, and B) filling a truck with a pile of bulk rape seed. In both cases, the Manitou loader developed a cyclic work: driving to the loading area, loading its front tool (either cup or fork) with the seed or package, driving to the unloading area, and releasing the load into the truck or warehouse. The detailed collection of data concerning the actual driving paths, the speed, the travelling times, the gears used at every transect, the fuel usage, etc., provided clues for understanding how was the real field efficiency of the machine during work.

In the following graphs, a schematic view of the registered data can be seen depicting both cases, the hay package unloading (A) and the truck loading with rape seed (B). Also the infrared cameras registered valuable information regarding the temperature of the oleo-hydraulic circuit and its efficiency.

The original article and more data can be found at the UPM’s digital repository https://oa.upm.es/22350/ and at the publishers web site (Magazine ‘Vida Rural’) in https://www.agronegocios.es/manitou-mlt-840-137-ps/