The use of automatic gearboxes during field work in modern tractors is hindered in many cases by the lack of trust from the tractor drivers. Quite often, users do not trust on how the automatic selection of gears will be done, being afraid of getting their tractors stuck in the middle of the field. If you talk to the drivers, some of them will even tell you “I like to be the one to select the gear in every moment, because I like the engine to maintain a louder noise, to be ‘happier’ ” – they say. But a “happier” engine means a higher regime (rpm), and that also usually means higher fuel consumption.

Modern semiautomatic or automatic gearboxes, including CVT (continuous variable transmission) have been engineered for many years now and are well proven to use less fuel than most professional drivers. Manufacturers repeat this fact as a mantra at every machinery tradeshow around the globe, but when it gets to the end user at the real work every day, many tractor owners switch the button inside their tractor to “auto gear off” and work most of the time in “manual mode”.

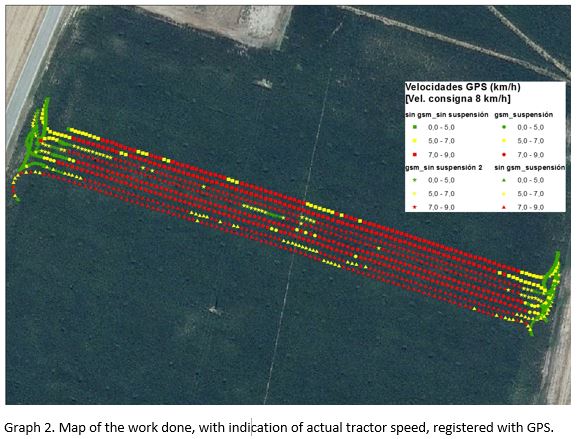

Fortunately, digital technologies such ISOBUS can help in convincing drivers to let their intelligent machine to do the gear work automatically. The LPF_Tagralia research group at Univ Politecnica Madrid has tested many tractors at the field, registering the data generated by the ISOBUS systems of the tractor (real speed, fuel consumption, power, torque, regime…). In the following illustrations a ploughing test is depicted (see full publication here), performed in 2012.

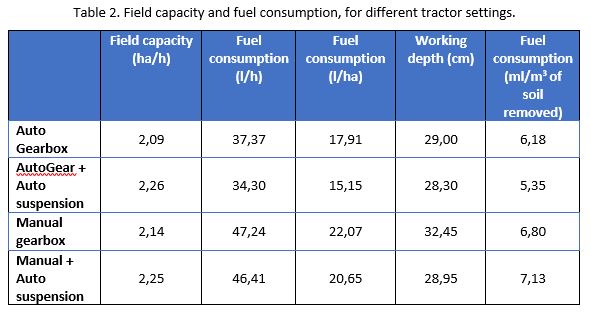

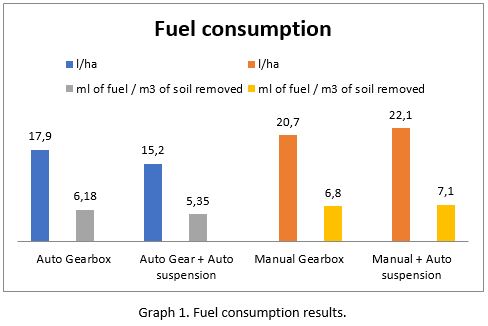

By analysing the collected ISOBUS data, it was easy to prove that, for such a demanding work (plough), fuel consumption when two automatic features of the tractor (auto-gearbox and auto-suspension) were actively being used was significantly lower than when the tractor was used in full manual mode by an experimented driver. According to the result of this test (see graph) the user could save up between 3 and 5 litres of fuel per hectare.

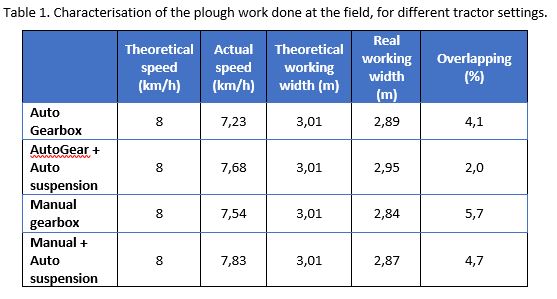

Looking carefully at the data provided by the ISOBUS files and the GPS recording, anyone could calculate other interesting parameters of the work done at the field, such as the real speed (km/h), real working width (m), overlapping (%) and actual field capacity (ha/h). See results in tables 1 & 2.

Digital recording allows us to obtain valuable information of the real work done every day at the farm, which is the first step in order to optimize our profitability.